The Fluke 77 multimeter is a trusted tool in automotive and industrial applications, known for its rugged design, accuracy, and reliability. It offers a wide range of measurement capabilities, including voltage, current, and resistance, making it versatile for various diagnostic tasks. With its high-resolution 6000-count display and both manual and autorange modes, it provides precise measurements for professionals and hobbyists alike. Its durability and adherence to safety standards ensure long-term performance in demanding environments.

1.1 Overview of Features and Capabilities

The Fluke 77 multimeter is a high-performance device designed for precise measurements in various applications. It features a 6000-count, 3 3/4-digit display, providing excellent resolution and accuracy. The multimeter supports manual and autorange modes, allowing users to select the best range for their measurements. It measures voltage, current, and resistance with high accuracy, and its maximum ratings include 1000V AC/DC and 10A AC/DC. The Fluke 77 also complies with industry safety standards, ensuring safe operation in hazardous environments. Its durability and reliability make it a favorite among professionals and hobbyists alike. Additional features include a rugged design, long battery life, and compatibility with various accessories. Whether for automotive diagnostics or industrial troubleshooting, the Fluke 77 delivers consistent and reliable results.

1.2 Importance in Automotive and Industrial Applications

The Fluke 77 multimeter is widely recognized for its versatility and reliability in automotive and industrial settings. In automotive diagnostics, it excels at troubleshooting electrical systems, measuring battery performance, and diagnosing alternator and starter motor issues. Its high accuracy ensures precise readings, which are critical for identifying faults in modern vehicles. In industrial environments, the Fluke 77 is essential for maintaining machinery, testing electrical circuits, and ensuring compliance with safety standards. Its durability and resistance to harsh conditions make it a trusted tool for professionals. Whether measuring voltage in industrial control systems or current in motor drives, the Fluke 77 delivers the precision needed for efficient troubleshooting and maintenance. Its portability and user-friendly design further enhance its value in fast-paced environments, making it an indispensable asset for technicians and engineers alike.

Safety Precautions and Guidelines

Ensure safe operation by wearing protective gear, avoiding hazardous environments, and following manufacturer guidelines. Proper usage prevents damage and ensures safety for both the user and the device.

2.1 Handling and Storage Tips

To maintain the Fluke 77 multimeter’s performance and longevity, handle it with care. Always use the provided test leads and avoid touching terminals with bare hands to prevent damage. Store the device in a dry, cool environment, away from direct sunlight and moisture. Use the original carrying case to protect it from physical damage. Avoid exposing the multimeter to extreme temperatures or mechanical stress, as this can affect its accuracy. Clean the device regularly with a soft cloth and mild detergent, ensuring no liquids enter the housing. Before storing, ensure all functions are turned off and batteries are removed if storing for an extended period. Proper handling and storage prevent wear and tear, ensuring reliable measurements and extending the device’s lifespan. Always refer to the user manual for specific storage recommendations to maintain warranty and performance standards.

2.2 Calibration and Maintenance

Calibration and maintenance are essential to ensure the Fluke 77 multimeter operates accurately and reliably. Calibration should be performed periodically, as specified in the user manual, to maintain measurement precision. Use Fluke-approved calibration tools and follow the manual’s instructions to avoid damaging the device. Regular maintenance involves checking and cleaning the test leads, ensuring they are free from damage or corrosion. Inspect the multimeter’s terminals and contacts for dirt or oxidation and clean them gently with an anti-static wipe. Avoid using harsh chemicals or abrasive materials, as they may damage the device. Additionally, ensure the multimeter’s firmware is updated to the latest version for optimal performance. Store the device in a protective case when not in use to prevent physical damage. Proper calibration and maintenance routines will extend the lifespan of the Fluke 77 and ensure accurate measurements in both automotive and industrial applications. Always adhere to the manufacturer’s guidelines for calibration and maintenance procedures.

2.3 Compliance with Industry Standards

The Fluke 77 multimeter is designed to meet rigorous industry standards, ensuring safety and performance in various applications. It complies with international safety standards such as IEC 61010-1 and EN 61010-1, which outline requirements for electrical test and measurement equipment. Additionally, the device adheres to North American standards like UL 61010-1. The multimeter is rated for CAT III 1000V and CAT IV 600V environments, making it suitable for use in industrial and high-voltage settings. Compliance with these standards ensures the device can withstand harsh conditions while providing accurate measurements. The Fluke 77 also meets electromagnetic compatibility (EMC) standards, minimizing interference from external sources. Always verify the device’s compliance with local and industry-specific regulations before use; By adhering to these standards, the Fluke 77 multimeter delivers reliable performance and safety for professionals in automotive, industrial, and electrical fields.

Understanding the Fluke 77 Specifications

The Fluke 77 multimeter is renowned for its precision and durability, offering a wide range of measurement capabilities. It provides accurate voltage, current, and resistance readings, along with additional features like capacitance and frequency measurement. Designed to withstand rugged conditions, the Fluke 77 ensures reliable performance in demanding environments, making it a trusted tool for professionals. Its specifications cater to both automotive and industrial applications, delivering high accuracy and versatility for various diagnostic tasks. The device’s robust build and advanced functionality make it a preferred choice for technicians seeking dependable results. With its comprehensive set of features, the Fluke 77 multimeter is a versatile instrument for measuring electrical parameters efficiently. Its reliability and durability ensure long-term performance, even in challenging work environments. The Fluke 77 is a testament to Fluke’s commitment to excellence in test and measurement equipment.

3.1 Voltage and Current Measurement Ranges

The Fluke 77 multimeter offers a wide range of voltage and current measurement capabilities, making it suitable for various applications. For voltage measurements, the device can handle up to 1000V DC and 1000V AC, providing high accuracy for both low and high-voltage systems. The current measurement range extends up to 10A, allowing users to measure both small and large currents effectively. The multimeter features multiple ranges for voltage (0.1V to 1000V) and current (1mA to 10A), ensuring precise readings across different scenarios. Additionally, the device supports both manual and autoranging options, giving users flexibility in selecting the appropriate range for their measurements. The Fluke 77 also includes safety ratings such as CAT III 1000V and CAT IV 600V, ensuring safe operation in hazardous environments. With its high accuracy and versatile measurement ranges, the Fluke 77 is ideal for professionals needing reliable voltage and current measurements in automotive, industrial, and electrical applications.

3.2 Resistance and Other Measurement Capabilities

The Fluke 77 multimeter is equipped with a robust set of features for measuring resistance and other parameters. It can measure resistance across a wide range of values, from 0.1Ω to 40MΩ, with high precision. The device also includes a diode test function, which helps in verifying the integrity of diodes and rectifiers. Additionally, the multimeter features a continuity test with a beeper, making it easy to identify short circuits or faulty connections. Beyond basic resistance measurements, the Fluke 77 can also measure capacitance, although this function is limited compared to dedicated LCR meters. For convenience, the multimeter supports both manual and autorange options, allowing users to select the most appropriate range for their specific application. Its versatility extends to measuring frequency on AC signals, further enhancing its utility in industrial and automotive diagnostics. These features make the Fluke 77 a comprehensive tool for troubleshooting and testing electrical systems, ensuring accurate and reliable results across a variety of tasks.

3.3 Display and Accuracy Details

The Fluke 77 multimeter features a high-resolution, 6000-count LCD display with a backlight, ensuring clear readability even in low-light conditions; The display is equipped with a bar graph that provides a visual representation of measurement trends, aiding in real-time analysis. With an update rate of 4 times per second, the device delivers smooth and responsive measurements. The multimeter offers exceptional accuracy, with a DC voltage accuracy of ±0.1% + 1 count, making it suitable for precise measurements in industrial and automotive environments. For AC voltage, the accuracy is ±0.5% + 1 count, ensuring reliable results across various applications. The device also supports autorange and manual range selection, allowing users to optimize measurements based on their needs. Additionally, the Fluke 77 complies with industry standards such as IEC 1010, guaranteeing safety and performance in demanding work conditions. These features make the Fluke 77 a trusted tool for professionals requiring high accuracy and reliability in their daily tasks.

How to Use the Fluke 77 Multimeter

Using the Fluke 77 involves selecting the correct measurement mode, connecting test leads properly, and ensuring the multimeter is set to the appropriate range for accurate readings. Always refer to the manual for specific instructions.

4.1 Selecting the Right Measurement Range

Selecting the appropriate measurement range on the Fluke 77 multimeter ensures accurate and safe readings. Always start by identifying the type of measurement (voltage, current, or resistance) and estimating the expected value. Choose a range that closely matches the expected measurement to maximize accuracy. For example, if measuring a 12V battery, select the 20V range. The multimeter’s autorange feature can automatically select the best range, but manual selection is recommended for precise control. Refer to the multimeter’s dial or digital interface to confirm the selected range. Using a range too low for the measured value can lead to overload or damage, while a range too high may reduce resolution. Always consult the user manual for specific range options and guidelines. Proper range selection is crucial for reliable results in automotive and industrial applications.

4.2 Measuring Voltage and Current

Measuring voltage and current with the Fluke 77 multimeter requires careful setup to ensure accuracy and safety. For voltage measurements, set the multimeter to the DC or AC voltage mode, depending on the source. Connect the black lead to the common (COM) terminal and the red lead to the voltage (V) terminal. Place the probes directly across the circuit or component to measure the voltage drop. For current measurements, switch to the DC or AC current mode and connect the black lead to COM and the red lead to the current (A) terminal. Always ensure the circuit is de-energized before connecting for current measurements to avoid damage. Never touch the leads while measuring live circuits. For higher currents, use the 10A terminal if available. The Fluke 77’s high-resolution display ensures precise readings. Always refer to the manual for specific mode settings and safety precautions to prevent errors or damage to the device.

4.3 Measuring Resistance and Other Parameters

To measure resistance using the Fluke 77 multimeter, set the device to resistance mode, typically marked by the ohm symbol. Connect the black lead to the common (COM) terminal and the red lead to the voltage (V) terminal. Ensure the circuit is de-energized for accurate readings. For best accuracy, select the appropriate range manually, though the autorange feature can also be utilized. Gently touch the probes to the two points in the circuit where you wish to measure resistance. The multimeter will display the resistance value in ohms.

For continuity testing, set the multimeter to continuity mode. A beep indicates a complete circuit. For capacitance measurement, select the capacitance mode and follow similar connection steps. Always ensure the multimeter is calibrated and leads are clean for precise measurements. Avoid measuring resistance in live circuits to prevent damage or injury. The Fluke 77’s high-resolution display ensures accurate readings, and features like data logging can enhance your workflow.

4.4 Using Autorange for Convenience

The Fluke 77 multimeter features an Autorange function, which automatically selects the most suitable measurement range for the detected input signal. This eliminates the need to manually adjust the range, saving time and minimizing errors. To enable Autorange, ensure the multimeter is in the desired measurement mode (e.g., voltage, current, or resistance) and allow the device to adjust the range automatically. A slow blinking cursor or an “AUTO” indication on the display confirms Autorange is active.

Autorange is particularly useful when the expected measurement value is unknown or variable. It ensures accurate readings without requiring prior knowledge of the signal’s magnitude. However, for precise measurements or when working with specific tolerances, manual range selection may be preferred. The Autorange feature enhances efficiency and convenience, making the Fluke 77 ideal for both novice and experienced users in automotive and industrial settings. Always refer to the multimeter’s display for confirmation of the selected range before proceeding with measurements.

Maintenance and Troubleshooting

Regular maintenance ensures the Fluke 77 multimeter performs accurately. Clean the device, check for wear on test leads, and replace batteries as needed. Troubleshooting involves identifying common issues like faulty fuses or calibration drift. Always refer to the user manual for detailed calibration and repair procedures to maintain precision and reliability. Proper care extends the lifespan of the multimeter, ensuring consistent and accurate measurements in demanding environments.

5.1 Cleaning and Calibrating the Device

Cleaning and calibrating the Fluke 77 multimeter are essential for maintaining its accuracy and performance. Start by turning off the device and removing the batteries to ensure safety. Use a soft, dry brush or an anti-static cloth to gently clean the exterior, paying attention to the display and input terminals. For more thorough cleaning, dampen a cloth with distilled water, but avoid liquids entering the device.

Calibration is critical for precise measurements. Use a Fluke-approved calibration kit or visit an authorized service center. The multimeter features an auto-calibration function, but manual adjustments may be required for specific ranges. Always refer to the user manual for detailed calibration steps. Regular cleaning and calibration ensure the device remains reliable and accurate, reducing the risk of measurement errors in critical applications.

Avoid using harsh chemicals or abrasive materials, as they may damage the device. Calibration should only be performed by trained personnel to maintain the multimeter’s certification and warranty. Proper maintenance ensures the Fluke 77 continues to deliver exceptional performance in automotive and industrial settings.

5.2 Replacing Batteries and Fuses

Replacing batteries and fuses in the Fluke 77 multimeter is essential for maintaining its functionality. Always start by turning off the device to ensure safety. For batteries, locate the compartment, typically found on the back, and open it using a screwdriver if necessary. Replace the old batteries with the correct type specified in the user manual, ensuring proper polarity to avoid damage or short circuits. Securely close the compartment to maintain the device’s integrity.

Regarding fuses, the Fluke 77 may have internal ones that require careful handling. Check if you’re authorized to replace them or if professional assistance is needed to avoid voiding the warranty. Use only manufacturer-recommended fuses to prevent potential issues. When handling internal components, use an anti-static wrist strap to prevent static discharge. After replacing the fuse, reassemble the device and test it to ensure proper operation.

Remember to follow the manual’s instructions precisely to avoid damage or safety hazards. If unsure, consulting a professional is advisable to ensure the multimeter continues to perform reliably. Regular maintenance ensures the device remains operational and accurate for all your measurement needs.

5.3 Common Issues and Solutions

The Fluke 77 multimeter, like any electronic device, may encounter occasional issues. One common problem is inaccurate readings, often caused by worn-out test leads or incorrect range selection. To resolve this, ensure leads are clean and functioning properly, and always select the appropriate range for your measurement. Another issue is battery drain, which can occur in older models due to prolonged use or forgotten auto-shutoff. Replacing the batteries with fresh ones typically solves this problem.

Display malfunctions, such as slow response or dimming, can be addressed by adjusting the contrast or replacing the batteries if they are low. Overloading the multimeter during high-voltage measurements may cause fuse damage, requiring replacement with the correct rating. If the device stops working entirely, check for blown fuses or internal component damage. For persistent issues, consulting the user manual or contacting Fluke support is recommended. Regular maintenance and proper usage can prevent many of these problems, ensuring reliable performance over time.

5.4 DIY Repairs and Upgrades

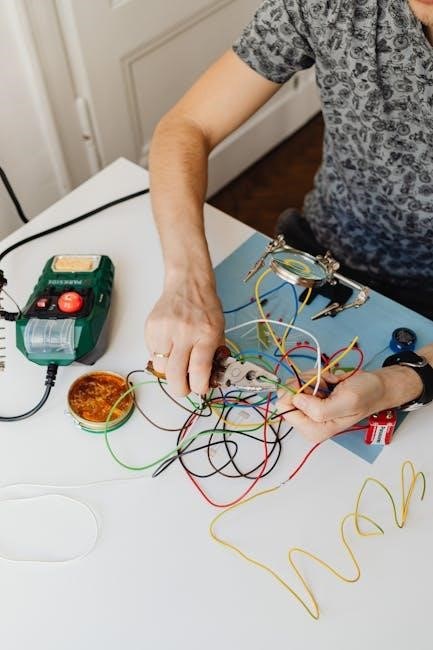

Performing DIY repairs and upgrades on the Fluke 77 multimeter can be cost-effective and extend its lifespan. One common DIY repair involves replacing blown fuses, which can be done by carefully opening the device and using the correct replacement fuse rating. Users can also upgrade the test leads to premium versions for better accuracy and durability. Additionally, cleaning the internal circuitry and contacts with compressed air or a soft brush can improve performance and prevent measurement errors.

For enthusiasts, upgrading the display backlight to an LED or enhancing the device’s ruggedness with a custom case can be done with minimal tools. However, complex repairs, such as replacing the internal PCB or recalibrating the device, should be avoided unless the user has advanced technical skills. Always ensure that any modifications comply with safety standards and do not void the warranty. DIY upgrades should be approached with caution to maintain the multimeter’s reliability and accuracy.

Accessories and Optional Equipment

The Fluke 77 multimeter can be enhanced with various accessories, including durable test leads, protective carrying cases, and advanced software tools for data logging and analysis, ensuring versatility and convenience in different work environments.

6.1 Test Leads and Probes

The Fluke 77 multimeter is typically used with high-quality test leads and probes designed to ensure accurate and reliable measurements. These leads are built with durable materials and are resistant to wear and tear, even in harsh environments. They come in various lengths and configurations to suit different tasks. The test leads are rated for Category III safety, providing protection against voltage spikes and electrical hazards. Probes with insulated tips are recommended for precise connections, reducing the risk of short circuits. For specialized measurements, optional probes such as thermocouple probes for temperature readings or current clamps for high-current applications can be used. Regular inspection of test leads is crucial to maintain performance, and damaged leads should be replaced immediately. Using genuine Fluke accessories ensures compatibility and optimal performance with the Fluke 77 multimeter, guaranteeing accurate results and user safety.

6.2 Carrying Cases and Storage Solutions

Proper storage and transportation of the Fluke 77 multimeter are essential to maintain its functionality and longevity. Fluke offers durable carrying cases designed specifically for the device, ensuring protection against dust, moisture, and physical damage. These cases are typically made of high-quality materials like hard plastic or nylon, providing excellent shock resistance. Many cases feature compartments for organizing test leads, probes, and other accessories, keeping everything neatly arranged. For added security, some cases include padding and secure closures to prevent accidental opening during transport. Additionally, storage solutions like anti-static bags or silica gel packets can be used to protect the multimeter from humidity and static discharge when not in use. Storing the device in a clean, dry environment is recommended to prevent corrosion or degradation. Regularly inspecting the multimeter and its accessories before storage ensures they remain in optimal condition for future use.

6.3 Software and Data Logging Tools

The Fluke 77 multimeter can be enhanced with specialized software and data logging tools to streamline measurements and analysis. Fluke offers compatible software solutions, such as Fluke Connect, which enables users to download and analyze data from the multimeter. This software allows for real-time monitoring, trending, and reporting, making it ideal for industrial and automotive applications. Data logging tools enable users to capture and store measurements over time, providing valuable insights for troubleshooting and maintenance tasks. The software also supports data export to popular formats like CSV or Excel for further analysis. Additionally, the Fluke Connect app allows wireless connectivity to mobile devices, enhancing convenience and collaboration. These tools not only improve efficiency but also ensure accurate and reliable data management. By integrating software and data logging capabilities, users can maximize the functionality of the Fluke 77 multimeter and simplify their workflow.